Finishing Applications

|

Dyeing FullCure Models

This application note is a guide for Objet 3D Printing Systems, users on how to enhance the detail, color and creativity of their FullCure™ models by applying special color dye techniques.

Highlighting one part of a model can bring the whole assembly to life. You can create a compelling presentation by adding a visual accent to any FullCure™ model using these simple dyeing and painting techniques.

|

|

|

|

Detailed Painting on FullCure Models

This application note is a guide for Objet 3D Printing Systems' users on how to enhance the detail, color and creativity of their FullCure™ models by applying special painting techniques.

Creating lifelike characteristics with accentuated, detailed features on printed FullCure™ models requires basic artistic skills and materials. A combination of various painting and dyeing techniques can be used to create the illusion of different material properties.

|

|

|

|

Gluing PolyJet Parts Application

When printing big parts, you can separate your design into several parts and then glue them together to create the full assembly.

You can do this using your CAD software before the design is complete, or by using STL file manipulation software after the CAD design is already completed.

|

|

|

|

Chemical Resistance Applications

Chemical resistance is considered a functional concern rather than an aesthetic one. Rapid prototype (RP) models designed to evaluate functional use within a chemical environment are subjected to various conditions, such as temperature, reagent combinations and concentrations, and exposure time, all of which affect chemical resistance.

|

|

|

|

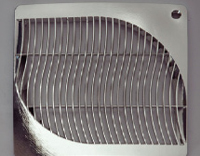

RF Shielding Applications

Electromagnetic shielding is the process of limiting the flow of electromagnetic fields between two locations by separating them with a barrier made of a conductive material. Typically, it is applied to covers or printed shells, separating electrical devices from the ‘outside world’ and to cables, separating wires from the environment through which the cable runs. Electromagnetic shielding used to block radio frequency electromagnetic radiation is known as RF shielding.

|

|

|

|

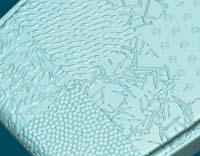

Rapid Texture Prototyping

Polyjet™ Technology can print textures (grains or patterns) and logos on prototype parts, molds and models exactly as they would be on final production molds or parts. If needed, the texture can be limited to specified areas. However, texture can also be added in a post-process using rapid texture prototyping applications.

|

|

|

|

Backlit Display

Backlit light box displays produce bright, vivid colors that are sure to grab attention, making them a great way to highlight your products and services. PolyJet technology allows us to produce superior results for longer-term indoor rapid prototyping applications.”

|

|

|

|

Vacuum Metallization

Vacuum metallization is the process of evaporating metals (most commonly aluminium) inside a vacuum chamber to achieve a uniform metalized layer.

|

|

|

|

Metal Coating

Metal coating can be successfully performed on PolyJet models to provide a decorative finish or a hard surface for wear in various rapid prototyping applications.

|

|

|

|

Textured Applications

The overgrowing use of textured parts and components in today’s industry has increased dependence on high-quality models. 3D printing of Objet’s parts provides the exact next step required to have these actual models in hand, printed in high-quality with remarkably fine details.

|

|

|

|

Penetrating Dye for Translucent Color

Color brings life to your models, and there is no simpler way to add color and preserve translucency than using aniline dye with PolyJet™ models.

|

|

|

|

Painting of PolyJet Parts

For sales samples, photography or finished models, painted PolyJet™ parts produced using Objet 3D Printing Systems will give your customers a compelling preview of your newest products.

|

|

|

|

Creating Clear or Translucent Models

Not all plastic parts are opaque. For clear parts such as lenses, containers, covers, panels and a variety of other rapid prototyping applications, Objet’s PolyJet™ Technology offers the advantages of rapid prototyping while also enabling the translucency required for the application.

|

|

|

|