Molding Applications

|

Silicone Molding with Objet Parts

Silicone rubber molding is a perfect solution to fill the gap between oneoff rapid prototyping and prototype injection molding. Silicone molds produce urethane castings that are used for functional testing, product demonstration and even low volume manufacturing. From rigid and tough to soft and flexible, quality parts can be made in less than a week at a low cost.

|

|

|

|

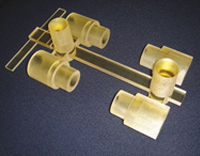

Rapid Tooling

Producing tooling directly from CAD models is regarded as an important method for reducing the cost and time to market of new products. Although this is a relatively new trend in manufacturing, it has already had a dramatic impact on the engineering environment.

|

|

|

|

Jigs & Fixtures

The cost of the jig was expected to be as high as $15,000-20,000 due to the large machine size and the high accuracy setting requirements. It was necessary to remove all major program risk as early as possible in the development period to make the jig work properly from the beginning.

|

|

|

|

Jewelry Molds Using VLT Rubber Process

The recent introduction of Castaldo® VLT™ [Very Low Temperature] molding rubber opens the way to a new time-saving process for jewelry molding using Objet Eden™ 3D Printing Systems.

|

|

|

|

Sand Casting Applications

Sand casting is an economical process for creating rough metal parts. Raw castings are then machined to produce finished products or components. Sand casting is the least expensive of all casting processes, including die and investment casting

|

|

|

|