Connex Applications

|

Overmolding

Overmolding is a molding process in which two or more materials are combined to produce a single part. Typically the part seamlessly binds a rigid plastic with a rubber-like elastomer. The result is a soft-touch, non-slip surface common on power tools, toothbrushes, razors, consumer electronics, medical devices and more.

|

|

|

|

Soft Touch Coating

In recent years, thermoplastic elastomers (TPE) based multi-material molded products have found widespread use in various industries and in daily life. The soft touch surface provides a non-slip grip and ergonomic comfort. Many industries use soft touch coating during their product design to validate future products. For example, the automotive industry uses soft touch in the design and development of interior products such as knobs, pulls and handles.

|

|

|

|

Labeling & Texturing

By printing two materials simultaneously, Connex printing systems are able to jet in different gray scaling settings for labeling and texturing. Furthermore, the high quality printing offered by Objet™ printers creates the fine details necessary for labeling and texturing. The unique combination of color scaling differentiation and excellent printing accuracy allows the user to generate texturing and labeling of the highest quality. This is especially important when a product must be displayed in "Gate Reviews" (approval meetings in which product designs are evaluated to determine if they will continue to the next stage in development).

|

|

|

|

Living Hinges

A living hinge is a thin flexible hinge (flexure bearing) made from plastic, as opposed to cloth, leather, or some other substance, that joins two rigid plastic parts. The hinge allows the plastic parts to bend along the line of the hinge. It is typically manufactured in an injection molding process that creates all three parts at one time as a single entity. A thinned section of the plastic part bends to allow movement.

|

|

|

|

Dynamic Friction Coefficient

Friction is defined as the force that opposes the relative motion or tendency of such motion of two surfaces in contact. The friction coefficient of a prototype’s surface is a functional component, not an aesthetic one, and simulates the end product’s mechanical properties. A well-designed prototype that takes friction into consideration can have the following advantages: an improved grip for the enduser, reduced part wear, simulated movement functionality and sliding abilities.

|

|

|

|

Gaskets Plugs & Seals

A plug is a piece of material used to stop up a hole or aperture, to fill a gap, or to act as a wedge. For example, plugs for sanitation are used to firmly close a drainage outlet in bathtubs, washbasins or sinks (see figure below). To ensure a tight seal, plugs are typically made from a soft material such as rubber or have a soft outer ring so that they can be fitted to holes slightly smaller than their diameter.

|

|

|

|

Shock Absorption

Shock/energy-absorbing components are often used as a safety measure to absorb runaway energy in case of a component or system failure.

Practical examples of shock absorbing components include bumpers, isolators, fasteners, mounts, spacers and pads.

|

|

|

|

Impact Resistance

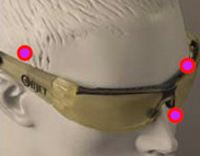

Impact resistance, or toughness, is defined by the relative susceptibility of plastics to fracture under stresses applied at high speeds. In materials science and metallurgy, impact resistance is a material's resistance to fracture when stressed. It is defined as the amount of energy per volume that a material can absorb before rupturing.

|

|

|

|